Overview

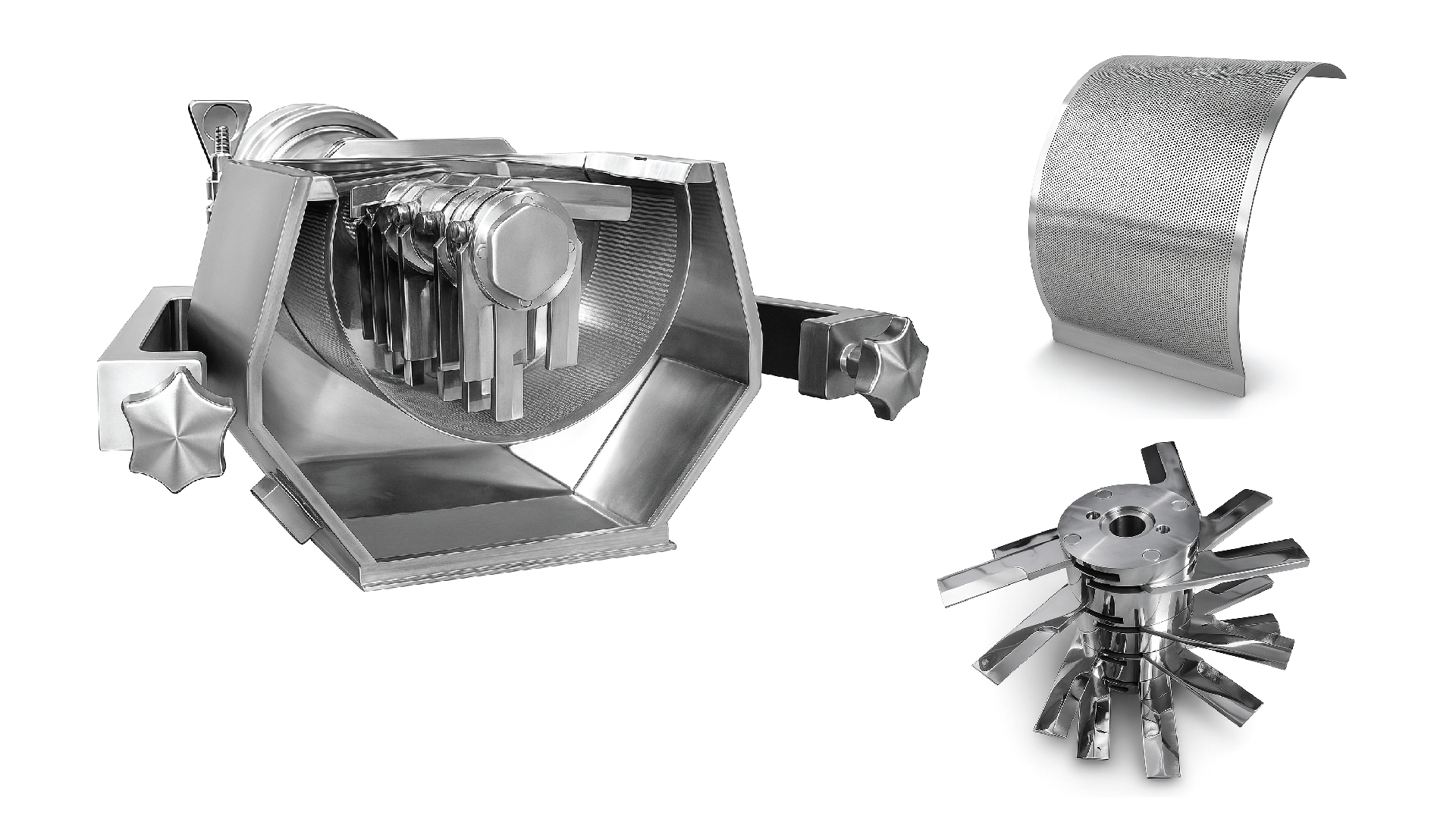

The 3-in-1 Mill Sizer combines milling, sifting, and sizing into a single machine, streamlining production processes. It offers precise particle size control, enhances efficiency, and is ideal for various industries like pharmaceuticals, food, and chemicals. Its compact design integrates easily into existing production lines, reducing operational complexity.

Key Advantages:

The outstanding features of Nhất Huy’s 3-in-1 Mill Sizer make it the top choice for pharmaceutical production and formulation:

✔ Fitz Mill Head (Hammer Mill): Efficiently grinds materials into fine powder, optimizing the drug processing workflow.

✔ Cone Mill Head: Adjusts particle size to ensure uniform quality for both dry and wet materials.

✔ Cone Mill Screen: Screens particles according to size, meeting quality standards required in pharmaceutical production.

Practical Applications:

- Pharmaceutical Manufacturing: Grinds and screens raw materials to produce medications

with consistent quality. - Material Processing: Refines ingredients for pharmaceuticals, nutraceuticals, and chemicals.

- Process Optimization: Combines three functions in one machine, saving both time and costs.

- Quality Assurance: Precisely adjusts particle size to meet high-quality standards.

Financial Benefits.

- Cost Savings: By integrating three functions (milling, sizing, and screening) into one machine, it reduces the need for multiple separate machines and lowers maintenance costs.

- Increased Productivity and Efficiency: Enhances production efficiency with the ability to precisely adjust particle size and ensure uniform screening, reducing production time and

costs, which maximizes profitability.